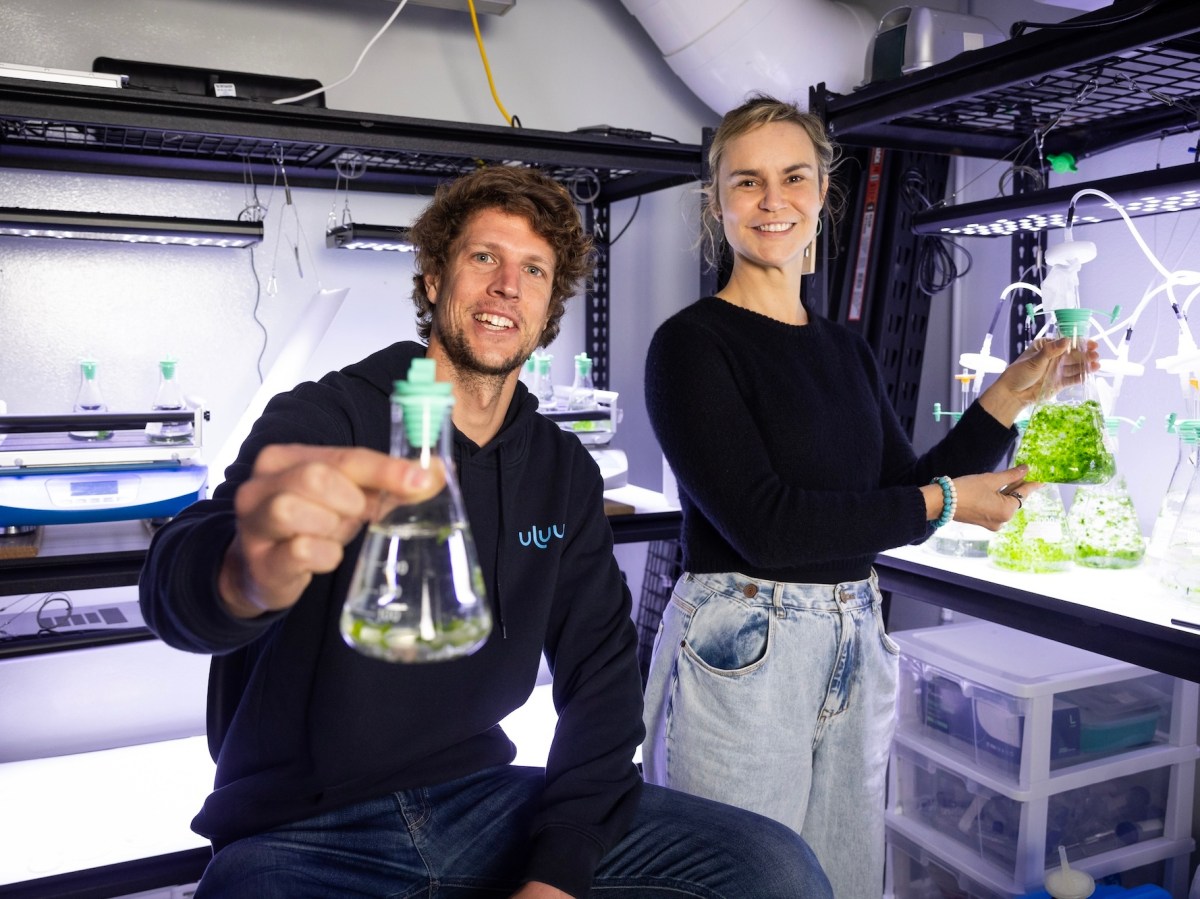

A Perth-based start-up with an ambitious plan to replace plastics with seaweed is now worth A$105 million following a $16 million Series A round.

Uluu’s world-first technology transforms seaweed into materials that look and feel like conventional plastic, but are reusable, recyclable, compostable, and marine biodegradable.

Co-founders and co-CEOs Dr Julia Reisser and Michael Kingsbury say the capital marks a major step toward industrial production and commercialisation, accelerating Uluu from its 100kg per year test plant to a 10-tonne-per-year demonstration plant in Western Australia.

Over the next 12 to 18 months, the company’s focus will be on completing construction of the new facility and supplying customers across cosmetics, fashion, and automotive industries with commercial-grade material for the first time.

The increased production will allow partner brands, including Quiksilver, Papinelle and Audi, to move from prototyping into staged trials, paving the way for the long-term offtake agreements needed to underpin Uluu’s first commercial plant.

“We’ve been running our test plant for two years and are now ready to scale up,” Reisser said.

“The $16 million enables us to increase production one hundred times from our current 100 kilograms per year, deliver significant volumes to customers, and give brands the confidence needed to enter multi-year offtake agreements ahead of our first commercial plant in 2028.”

If all goes to plan, Uluu expect to return to market for a larger Series B funding round to support the build of a much bigger facility. That commercial plant is expected to be operational in 2028, initially producing around 3,000 tonnes a year before ramping up to 10,000 tonnes by 2030.

Cutting global CO₂ emissions

The company estimates that at commercial scale its product could sequester and avoid up to five kilograms of carbon dioxide equivalent for every kilogram of material produced, compared with about three kilograms emitted by plastic today.

The technology has the potential to one day reduce global CO₂ emissions by more than 2 gigatonnes per year. By comparison, India’s annual CO₂ emissions are around 2.8 gigatonnes.

“Seaweed grows quickly and gets everything it needs from the sun and the sea,” Reisser said.

“It locks away CO₂ and helps clean up pollutants from the ocean. By harnessing seaweed, Uluu is producing materials that have a positive, rather than negative, impact on the environment, while ending plastic pollution.”

Investors step up

This is the third time Uluu has raised external capital, raising A$1.3 million in 2021 to try and get the idea up and running, and adding a further A$8 million in seed capital in 2022, led by Main Sequence – the CSIRO’s venture capital arm, with participation from Albert Impact Ventures, Mistletoe and Possible Ventures.

The latest funding round was led by Burda Principal Investments – the growth arm of Germany’s Hubert Burda Media – with participation from Main Sequence, Novel Investments (the family office of one of the world’s largest textile groups, Novetex Textiles), Startmate, and a consortium of impact investors including Fairground and Trinity Ventures.

Christian Teichmann chief executive of Burda Principal Investments said:

“At BPI, we invest in companies driving transformative innovation with the potential to become a global category leader. Uluu is redefining how materials can be produced more sustainably at an industrial scale.”

Kingsbury added that having Australian deep tech investor Main Sequence on its board has provided access to a lot of relevant industry expertise as the company thinks about how to derisk its technology and demonstrate traction to other investors.

“Ultimately, we want to be able to shift away from equity financing to become a bankable business that can raise debt to go and build a commercial scale plant,” Kingsbury said.

Join the OnImpact mailing list to receive the latest impact investment news and updates.